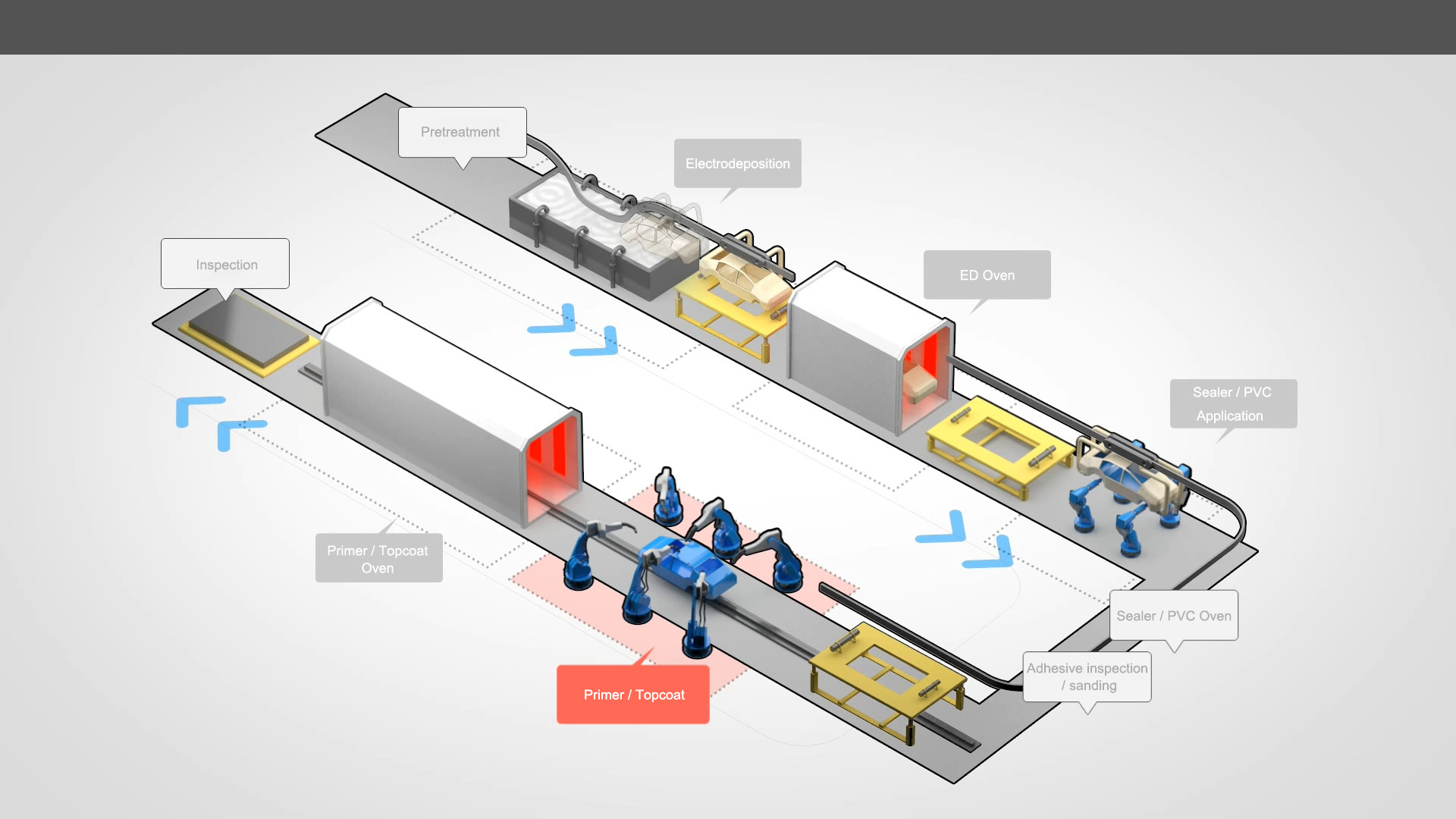

1. Magani: Domin cire man da ba dole ba, ragowar walda, da ƙazanta daga saman abin shigar da jikin abin hawa daga masana'antar jiki, fim ɗin zinc phosphate (3 ~ 5)㎛) ana amfani da shi a jikin jiki don ƙara yawan mannewa a lokacin rufewa (electrodeposition). tsari. Don manufar kariya ta lalata jikin mota.

- Tsaftacewa: Bayan an gama hada jiki, ana wanke shi da ruwa kafin a wanke shi sosai.

- Main ragewa: Yana cire mai daga jikin mota.

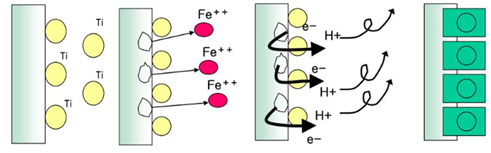

- Kurkura sharaɗi: Wani wakili na jiyya tare da titanium a matsayin babban ɓangaren, ƙirƙirar adadi mai yawa na colloid akan saman ƙarfe don ƙara haɓakawa don ƙirƙirar fim ɗin zinc phosphate mai yawa don samar da lu'ulu'u masu kyau da yawa.

- Fim ɗin Zinc phosphate: Ana amfani da fim ɗin zinc phosphate don ƙarfafa mannewa na undercoat da hana lalata halayen.

1) Etching yana farawa a ɓangaren anode na takardar karfe a cikin maganin shafi

2) Dangane da lalata halin yanzu, cations suna cinyewa a cathode, kuma pH na dubawa yana tashi.

3) Colloid a saman ya zama tsakiya da crystallizes

- Ruwa busassun tanda: Tsarin cire gaba ɗaya danshi daga cikin substrate bayan an gama aikin riga-kafi.

※ Canja wurin zafi da bushewa a bushewar hannu

Bayan an rufe jiki da fim ɗin zinc phosphate ( ), wanke shi da ruwa kuma a bushe shi da hannu. Bushewar yanke da hannu tsari ne na cire danshi gaba ɗaya daga abin da za a shafa sannan kuma aiwatar da aikin zane na gaba. Haɓaka zafin jiki don ƙafe danshi ta hanyar canja wurin zafi. Bushewa (evaporation) al'amari ne da ke faruwa a lokacin da zafin daɗaɗɗen saman da ke hulɗa da shi ya yi ƙasa da wurin tafasa kuma yanayin yanayin ya yi ƙasa da matsa lamba. canji lokaci zai faru. Zazzabi da lokacin da ake buƙata don tanderun bushewa da aka yanke da hannu sun bambanta dangane da kayan, kauri, da siffar abin da za a shafa. Yawancin lokaci, minti 10 a 120 ~ 150 ℃ na kowa, kuma dalilin haɓaka zafin jiki shine ƙara yawan tururi na ruwa wanda ya dace da wannan zafin jiki kuma ya bushe da sauri ta hanyar samar da karin makamashin zafi. A wannan lokacin, bai kamata a sami canjin ƙarfe ko sinadarai ba saboda yanayin zafi.

1,Tsarin Electrodeposition: Tsarin samar da fim ɗin shafa a ciki / waje na jikin abin hawa ta hanyar amfani da electrophoresis ta hanyar lantarki bayan nutsar da jikin abin hawa a cikin fenti na lantarki, don hana lalata jikin abin hawa.

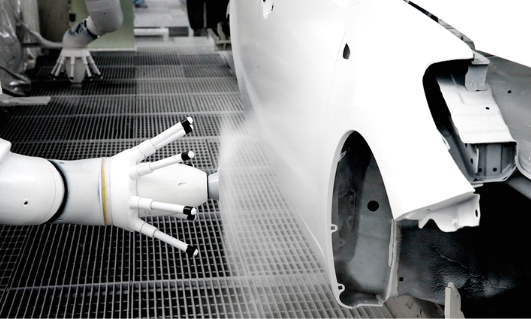

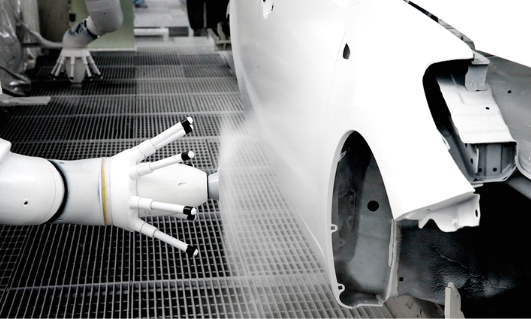

- Electrodeposition: Zanen Electrodeposition shine tsarin zane wanda ake haɗa fenti ta hanyar lantarki ta hanyar nutsar da jikin motar a cikin maganin fenti da anode ko cathode mai gudana ta jikin motar. Duk da haka, hanya ce da ta dace don samar da taro, kuma yana da wuya a sake fenti da zarar an haɗa fim ɗin mai rufi kuma wutar lantarki ba ta gudana.

- DI kurkura

- Electrodeposition Drying Furnace: Don cationic electrodeposition coatings, wanda aka yafi amfani, wani zafi-bushe tanderu da ake amfani da zafi-bushewa tanderu saboda ajiye fim a kan surface ne smoothed da thermal fluidization ta thermal crosslinking (thermal curing) dauki. Zazzabi da lokacin da ake buƙata don magance zafi sun bambanta dangane da kayan, kauri, da siffar abin da za a shafa. A cikin yanayin ɗan ƙaramin abu mai laushi mai ɗanɗano, yanayin zafin jiki shine 200-210 ° C kuma zafin wutar tanderu shine 210-230 ° C, kuma lokacin dumama shine gabaɗaya mintuna 20-30 gabaɗaya na mintuna 10 ko fiye don lokacin dumama abin da za'a shafa da 200-210 ° C lokacin riƙewa.

- Electrodeposition polishing: Niƙa da m da protruding sassa na saman don sa shi santsi.

2. Halfway Paint: Wannan ita ce hanyar yin amfani da fenti, wanda galibi ana kiransa da abin share fage. Yana tsaftace saman don saman gashin ya manne da kyau kuma yana taka rawa wajen inganta juriya na lalata. Ina amfani da launi daban-daban don tsakiyar don dacewa da launi na saman riga.

- Tsari mai tsaka-tsaki

- Matsakaicin bushewa tanderu

3. Kofi: Hanyar yin amfani da launi na abin hawa da ake iya gani da kuma ƙare tare da fenti mai haske. Kwanan nan, saboda ƙa'idodin muhalli, da dai sauransu, ana amfani da fenti masu dacewa da muhalli (ƙananan abubuwan da ba su da ƙarfi) a hankali. Share bayan saman gashi

- saman gashi tsari

- Topcoat bushewa tanderu

※ Canja wurin zafi a cikin electrodeposition / tsakiya / saman gashi dumama da bushewa tanderu

A cikin tanderun bushewa, ana canja zafi zuwa saman fentin ta hanyoyi biyu.

Convection: Domin sauƙi isa ga thermal curing zafin jiki na shafi fim, da sauri iska kwarara da ake bukata, da kuma high gudun convection aka samu ta hanyar zagawa da zafi iska a cikin bushewa tanderu a wani babban iska gudun (tilas convection).

Zafin Radiant: bangon yana dumama har zuwa digiri ɗari da yawa sama da yanayin zafin fim ɗin shafa a cikin tanderun bushewa na musamman da aka ƙera, kuma zafi mai zafi yana watsa zuwa saman fenti kamar yadda murhu ke dumama jiki.

Lokacin aikawa: Nuwamba-08-2022